CoolPMS - Power plant SCADA

CoolPMS is cost effectve, full scale version on SCADA system developed for InteliSys, InteliGen, InteliMains and other conrol hardware manufactured by ComAp. And Symap® controllers manu- factured by Stucke Elektronik GmbH. CoolPMS is a custom designed SCADA system for various applications to fulfill their specific requirements. Our primary target are customers who wants to implement top edge SCADA solution into their projects, but have no capacity, time or resources to develop their own supervisory control and data acquisition system. Detailed info about controllers and other products can be found on ComAp or Stucke Elektronik website.

Software Features

- Simultaneous monitoring up to 32 units

- Real time historical Trends & Alarms

- Data logging to SQL database

- Daily backup of historical trends

- Reporting capabilities to PDF or XLS

- Statistical calculations of the plant

- Embedded control logic

- Station Event logger

- Client/Server mode up to 8 clients

- TCP/IP or USB Multi-Camera monitor

- OEM design for system integrators

Hardware Features

- Touch screen or mouse control

- Support for ComAp IV17 Touch

- Support for ComAp IV118 Touch

- Resolution 1280x1024 up to 1920x1080

- Fulll HD television or monitor

- Embedded industrial PC - Intel J1900

- Ethernet RJ45, RS232, RS485

- Modbus RTU and Modbus TCP

- VESA 100 mounting available

- Interface for mamera monitoring

- IP65 front panel protection

Screen size and resolution

Connection topology

CoolPMS stationcan be connected to physical layers like RS485, RS422, RS232 and Ethernet. Below shown pictures represents examples of possible communication options. Both topologies - Serial and Ethernet can be mixed together.

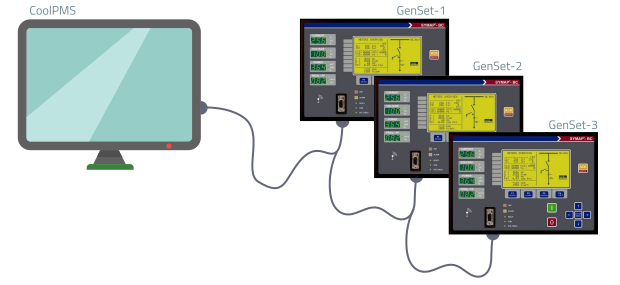

RS485 basic configuration

PC station is communicating with remote network nodes via RS485 multi-drop topology. Software layer is running Modbus RTU protocol. Optional Modbus RTU line is connected to external PLC for I/O monitoring. For detailed info about Modbus RTU please refer to datasheer of particular controller.

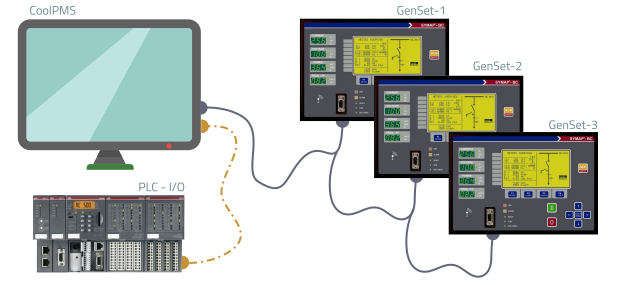

RS485 extended configuration

PC station is communicating with remote network nodes via RS485 multi-drop topology. Additional RS23 or RS485 or Ethernet TCP/IP connection to additional PLC/Alarm system could be made. Software layer is running Modbus RTU protocol. For detailed info about Modbus RTU please refer to datasheer of particular controller.

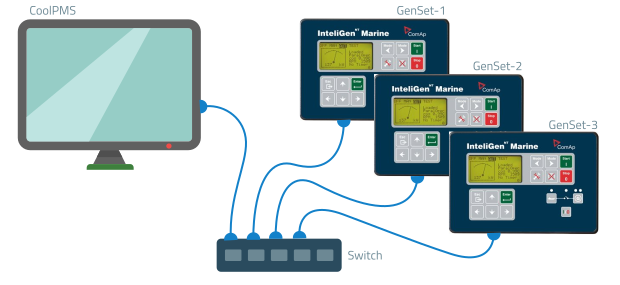

ETHERNET basic configuration

PC station is communicating with remote network nodes via Ethernet TCP/IP. Software layer is running Modbus TCP protocol. For detailed info about Modbus TCP infrastructure please refer to datasheer of particular controller.

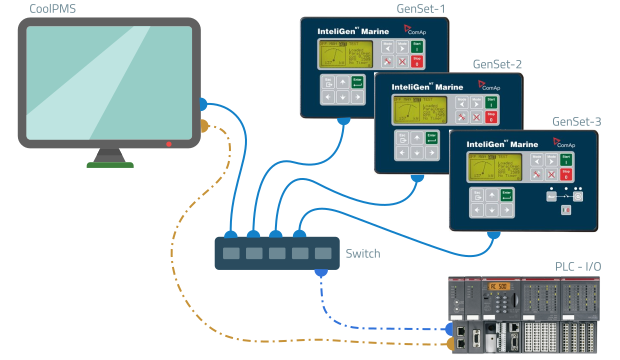

ETHERNET multi device configuration

PC station is communicating with remote network nodes via Ethernet TCP/IP. Software layer is running Modbus TCP protocol. Optional Modbus TCP or Modbus RTU line is connected to external device for I/O monitoring. For detailed info about Modbus TCP infrastructure please refer to datasheer of particular controller.

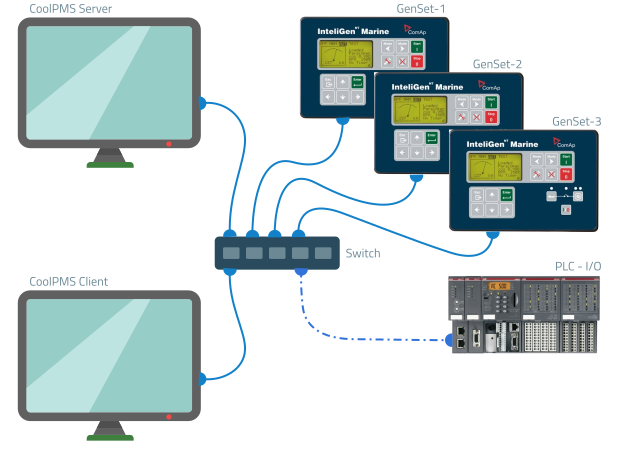

ETHERNET multi station configuration

PC stations are in Client/server mode. Server is communicating with remote network nodes via Ethernet TCP/IP. Software layer is running Modbus TCP protocol. Optional Modbus TCP line is connected to external device for I/O monitoring. Client has access to data from Server and serves as another remote station. For detailed info about Modbus TCP infrastructure please refer to datasheer of particular controller.

Company Services

Programming Support

We do provide programming services and support for ComAp / Symap® products as well as for other hardware vendors. Programming of PLC's on IEC61131 - CODESYS automation platform is our very strong domain.

Engineering and Consulting

We are helping customers with their PMS, SCADA and PLC projects, automation, system design and integration of ComAp / Symap® products. We can create specification, design hardware configuration and/or supply electrical CAD drawings for particular project

Commissioning and Troubleshooting

Commissioning and troubleshooting support for panel builders and end users of ComAp / Symap® products is most demanded service.

Networking and Communication

Integration of hardware components from different vendors may be difficult task. We can provide expertise and relevant solution how to connect and communicate data between multiple systems and various brands.

Graphics Design

We can design artistic templates and OEM screens for various customized SCADA and HMI projects.